| Payment Type: | L/C,T/T |

|---|---|

| Incoterm: | FOB,CIF |

| Min. Order: | 1 Bag/Bags |

| Delivery Time: | 180 Days |

Basic Info

Model No.: JF2200

Condition: New

Customized: Customized

Certification: Other

Protection System: Heating Protection, Lifting Protection

Automatic Grade: Automatic

Driven Type: Electric

Applicable Film Coating Resin: EVA,EAA Coating Level

Extrusion Coating Maximum Width: 1850 Mm

Extrusion Coating Thickness: 0.012-0.05 Mm

Extrusion Coating Thickness Error: ≤±4% Mm

Extrusion Coating Line Speed: Max.150 M/min

Maximum Extruding Volume: 350 Kg/h

Guide Roller Width: 2020 Mm

T-die Width: 2260 Mm (including Blanking Plate)

T-Die Effective Width: 2200 Mm

Additional Info

Packaging: by safety seaworthy packing

Productivity: 150 M/MIN

Brand: S

Transportation: Ocean

Place of Origin: CHINA

Supply Ability: 100 SETS PER YEAR

Certificate: C

HS Code: 8477

Port: SHANTOU

Product Description

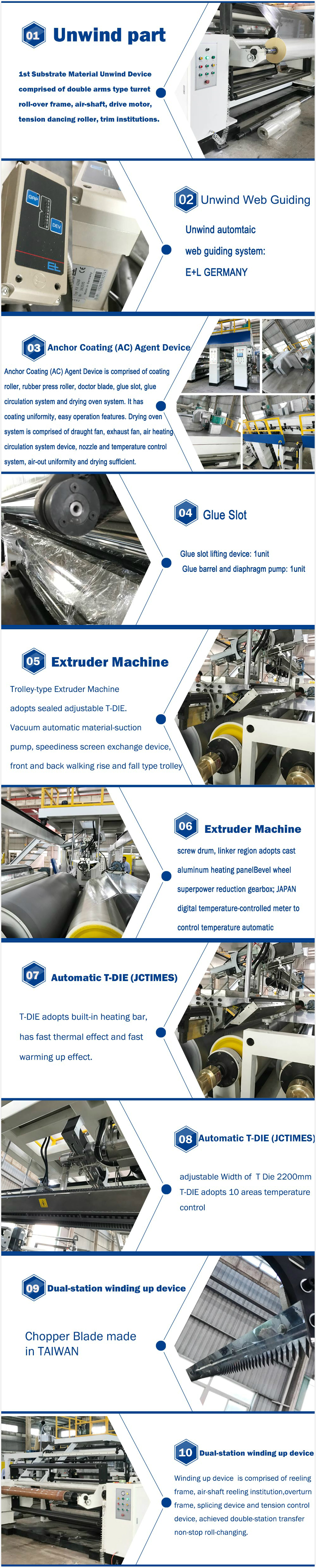

BOPP Thermal Film Extrusion Laminating Machine JF2200

Film Laminating machine BOPP Thermal Film Extrusion Laminating MachineJF2200 is the advanced products elaborately manufactured by our factory combined with actual production condition.

The structure of this machine is reasonable, appearance is novelty, easy to operate and maintenance, less energy consumption,

high efficiency, products enjoy excellent quality, which is the ideal equipment for producing BOPP, BOPET thermal film.

Film Laminating machine BOPP Thermal Film Extrusion Laminating Machine JF2200 is comprised of EVA, EAA, extrusion level resin to be raw material, it adopts casting type extrusion technological and substrate material (such as BOPP, PET film) to process one side coating production so that enhanced the strength of extension, fasten of laminating, and moisture barrier comprehensiveness performance, it is widely used for thermal lamination films industries.

Dual-station substrate material unwind adopts ultrasonic automatic web guiding system, substrate material is oriented automatic and web guiding control. Air-shaft loading material, unwind full-automatic tension control, high-speed non-stop automatic splicing continuous production. Casting segments cooling roller adopt forced water-cooling structure, good cooling effect. Winding up segments adopts double working station structure, full-automatic tension control, non-stop shaft exchanged, automatic splicing. Each technology roller clutch of complete machine controlled by pneumatic system.

Applicable film coating resin: EVA, EAA coating level

Extrusion coating maximum width: 1850 mm

Extrusion coating thickness: 0.012-0.05 mm

Extrusion coating thickness error: less than or equal to ±4% mm

Extrusion coating line speed:Max.150 m/min

Maximum extruding volume:350 kg/h

Guide roller width:2020 mm

T-Die width:2260 mm (including blanking plate)

T-Die effective width:2200 mm

Unwind maximum diameter:800 mm

Rewind maximum diameter:800 mm

Paper-core specification:6 inches

Extruder power:110 KW

Screw diameter:135mm L/D 28:1

Compressed air demanded:0.6 m3/min

Compressed air pressure:0.7 MPa

Electrical power supply:3 phase 5 cables 380V 50Hz

Full machine power:About 300 KW

External dimension:11.5m x 8m x 3.8m (L x W x H)

Full machine weight: About 30 tons

More Details as follow:

Company Information:

Sunny Machinery Factory is an integrated professional manufacturer to produce, design and sell Slitting, Rewinding, Laminating, Coating, and CPP or CPE 3 or multiple layers Cast Film machinery facilities with more than 19 years of experiences.

Our company has been developing and moving towards a greater competitive advantage by continuously improving technology and innovation.

All project will be serviced by our expertise in Mechanical Engineer Department, Assembly Department, Electrical Department, Software Programming Department, so we can offer our clients with our top standard machinery, also we can make all kinds of modifications according to customer specific requirements.

Our machineries are sold in many countries including India, Indonesia, Thailand, Vietnam, Brazil, Poland, Korea, Italy, Philippines, Singapore, Russia, Malaysia, Pakistan and so on.

© 2019 CHINA WAY. All Rights Reserved. SUNNY MACHINERY, Inc. All rights reserved. site map. sitemap.html